- Seasoned with over 20 years of Footwear Design experience.

- Known for creativity and professionalism amongst top tier athletes.

- Equipped with sample development capabilities through strong international manufacturing factory relationships.

- Dedicated to bringing quality footwear product to market in a timely manner.

DESIGN

Shoe Design process happens in 3 phases: Align, Design, Refine.

Confirm product brief, constraints, and success criteria.

What Happens

– Define product intent: use case, consumer, price point, etc

– Confirm constraints (timeline, costing, materials)

– Competitive analysis of the target market

How I Work

– Ask strategic questions early

– Translate business goals into footwear design direction that defines how the shoe should look and feel before design begins.

Outcome

– Shared vision: A decision-making system that allows multiple contributors (design, development, factory) to make aligned decisions without reinterpreting the vision each time.

– Clear expectations: What the shoe isn’t as much as what it does deliver, preventing endless revisions, ensuring consistency across samples, and ultimately saving time and money downstream.

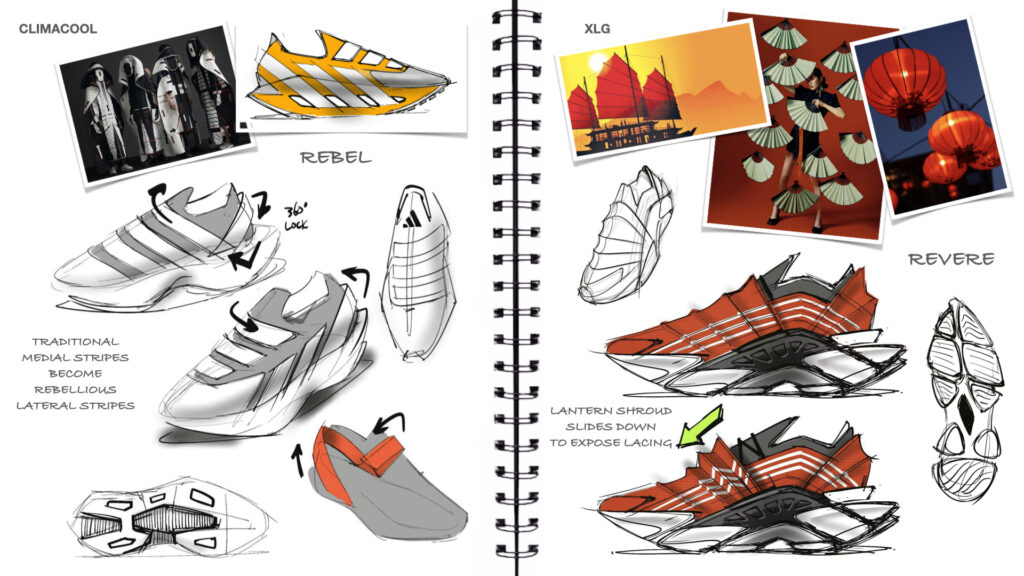

Translate inspiration into solution-based design.

What Happens

– Through 2D sketch exploration, establish a design framework that informs language, proportion, storytelling cues and brand expression.

– Exploration of color placement and material application.

– Consideration of textures and graphic applications that further assign significance to the shoe.

How I Work

– Iterate quickly and intentionally.

– Keep storytelling at the forefront.

– Take concepts to their limit.

Outcome

– Initial sculpting of the form, fit and function.

– Strong conceptual foundation of the overall attitude and proportion of the shoe.

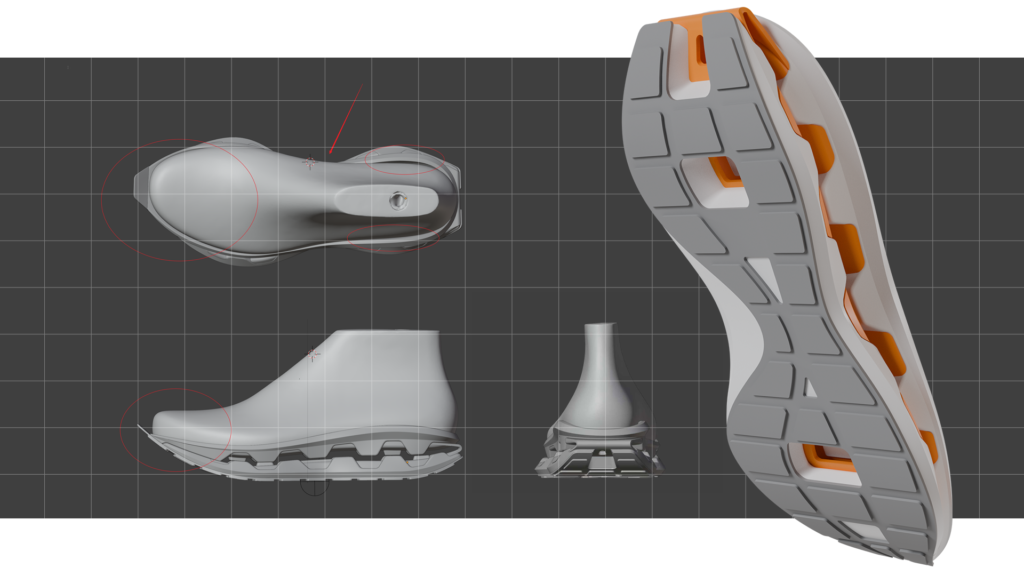

Finalize shoe design and assign detailed specifications.

What Happens

– Review final design details (proportions, lines, branding, materials) via 2D, 3D or AI renderings.

– Assign accurate measurements of all components, callout finishes and executions, provide material references.

How I Work

– Lead focused conversations that provide clear rationale behind design decisions.

– Balance client feedback with design integrity.

– Determine which materials are functionally and financially feasible, and which constructions are most logical for the design intent.

Outcome

– Fine-tuned aesthetics and performance intent that creates confidence moving into development phase.

– Tech pack that matches design complexity with vendor capability.

DEVELOPMENT

Once the shoe design is in motion, I stay close to the process to guide your shoe to its first real sample. I work alongside development partners to help sort through fit, materials, and construction decisions. When questions come up – and they always do – I make sure the shoe still feels true to the original idea.

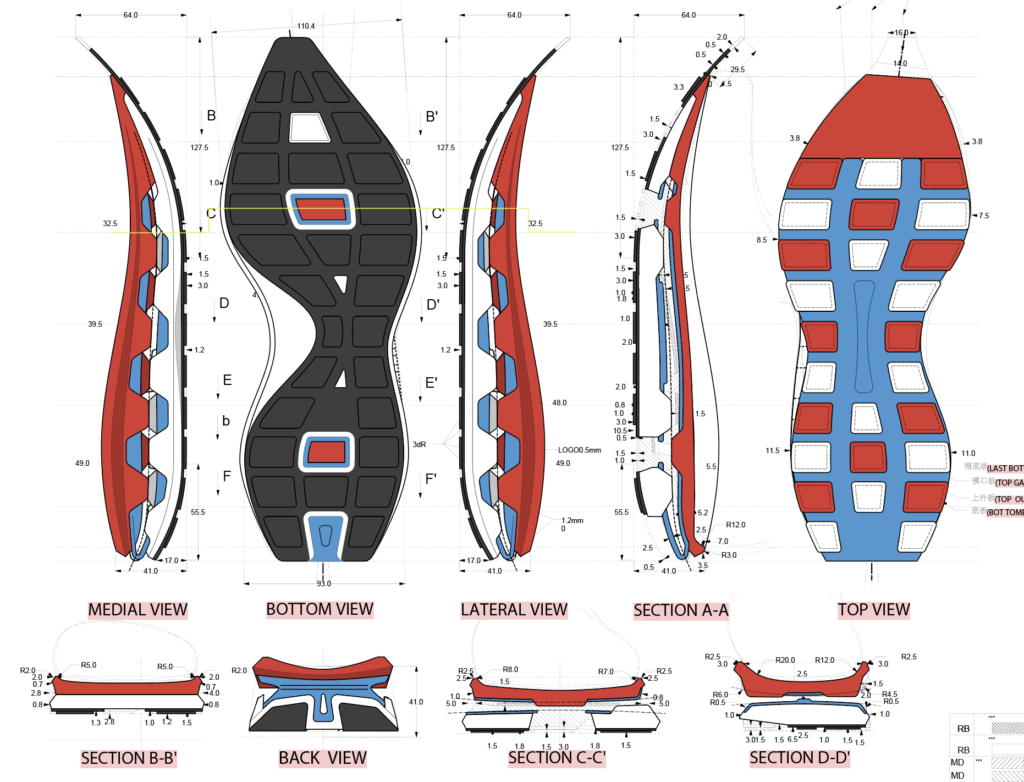

– Translate design intent into clear, buildable documentation.

– Ensure no gaps between design and development.

– Reduce misinterpretation.

Clean handoff of bilingual (EN/CN), production-ready design package to development | 3D visuals can be used to give manufacturers more clarity | Confirm sample order requirements (size range, quantities, colors)

Adjusting pattern for fit and comfort | Ensuring visual accuracy of design intent | Technical trials (printing, cutting, embossing, welding, etc.)

Careful inspection of digital and physical 2D and 3D CADs and models of all outsole and midsole components | Revisions made to reflect manufacturing feasibility and performance requirements of the shoe

Materials are selected to match performance needs (durability, breathability…) | Color matching across components

Final sample is examined for design accuracy and color correctness | Tested for fit, comfort, performance, material integrity, weight, etc.

Strategic direction on design, color and material costs| Construction methods re-evaluated for production readiness | Suggestions to improve weight, performance, and comfort based on testing.

PACKAGING

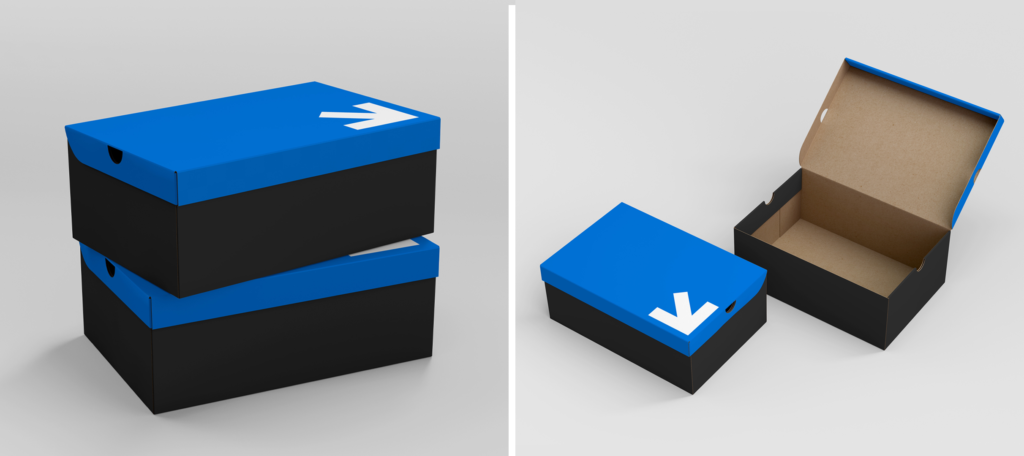

Choose from these shoe box styles and start sampling your packaging design, box labels and tissue paper.

TWO-PIECE

CLAMSHELL

HANDLE

PRODUCT SHOTS

Presentation is EVERYTHING! Don’t come this far to have your product not jump off the screen. Create eye-catching visuals that do your shoe’s story justice.

I’m a shoe designer specializing in shoe design for sneakers and performance footwear. My shoe design approach is shaped by the cultural influence of Kanye, the legacy of Air Jordan, and the evolution of Nike Basketball, including work connected to Kyrie Irving. From lifestyle sneakers to high-performance athletic shoes, the focus is always on thoughtful design and wearability.

PHOTOGRAPHY

3D MODEL (1:1)

3D ANIMATION

Follow my YouTube for more stories of a ahoe deigner who has been creating athletic snaekers for over 20 years in the footwear industry.